College of Science, University of Shanghai for Science and Technology, Dr. Weiju. Hao cooperated with Dr.Yanhui.Guo from the Department of Materials, Fudan University to publish articles in top international journals of Energy Environ. Sci.(Cite this: Energy Environ. Sci., 2020, 13, 102)The title of paper is “Fabrication of practical catalytic electrodes using insulating and eco-friendly substrates for overall water splitting”. The latest impact factor of the journal in 2020 is 32.190.

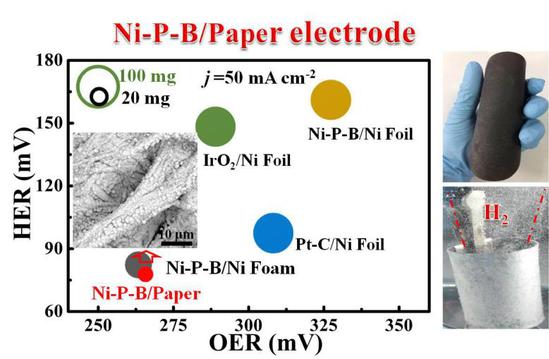

The development of efficient and cost-effective catalytic electrodes is of great importance to electrolysis. Currently, electrolysis of water that can produce hydrogen using a cheap source of electrical energy is driving extensive research efforts to address increasing global energy challenges and related environmental issues. Normally, a catalytic electrode is fabricated by deposition of active electrocatalysts on conductive substrates of metal, carbon cloth and semiconductor. Despite the advanced progress in the development of electrocatalysts, an extension of the substrate to inexpensive and eco-friendly materials will be of great practical interest and environmental benefit. A family of catalytic electrodes fabricated on insulating substrates of paper, cloth and sponge which bring dramatic advantages of high performance, low cost, light weight, eco-friendliness, flexibility, and simple and scalable fabrication, were developed. One of the electrolyzers assembled by the bifunctional Ni-P-B/paper electrode, which is only 1/5 the weight of the electrode with a common Ni foil substrate, delivered a current density of 50 mA cm-2 at a cell voltage of only 1.661 V for overall water splitting, rivalling most of the electrodes constructed by traditional conductive substrates. Meanwhile, the novel electrode can also survive at large current density of 1000 mA cm-2 for over 240 h without apparent performance degradation in 1.0 M KOH.

In this paper, we have developed a family of robust catalytic electrodes by depositing conductive catalysts on insulating substrates of paper, cloth and sponge, which bring dramatic advantages of high performance, low cost, lightweight, eco-friendliness, flexibility, and simple and scalable fabrication. One of the electrolyzers assembled by a Ni-P-B/paper electrode which can survive at large current density of 1000 mA cm-2 for over 240 h, delivered a current density of 50 mA cm-2 at a cell voltage of only 1.661 V for overall water splitting. The remarkable performance of the catalytic electrodes may be attributed to a combination of high conductivity, active electrocatalyst and favourable structure. Further advances in the degradation performance could promote the practical application of the catalytic electrodes. Moreover, a ring Ni-P-B/paper electrode that enables in situ generation and collection of H2 and O2 products has been constructed by a filter paper substrate. This work may open scientific and engineering opportunities in the development of cost-effective, efficient and more eco-friendly electrodes for a wide variety of applications.

Link of article:

https://pubs.rsc.org/en/content/articlelanding/2020/ee/c9ee00839j#!divAbstract